Understanding CNC Turning Parts: 3 Things to Know

If you’re new to the world of machining, it may be exhausting trying to learn everything at once. For example, CNC turning is one of the most common forms of machining, and understanding it is key to succeeding in the modern manufacturing world.

Whether prototyping a new design or scaling up, CNC machining can help you achieve your dreams. So, what are CNC turning parts? How do they work?

Don’t worry. We’ve got you covered. Here are three essential things to know about CNC turning.

Table of Contents

1. Overview of CNC Turning Parts

CNC turning is a machining process that uses a lathe to cut a workpiece that is rotating around its central axis. It is an effective way to fabricate precision parts with high mechanical tolerances. Here are three things to understand when using CNC turning parts:

Geometry

Parts created using CNC turning need simple shapes like cylinders and discs. Complicated geometries such as non-circular or non-uniform grooves can be created, but they are much more complex and require special programming.

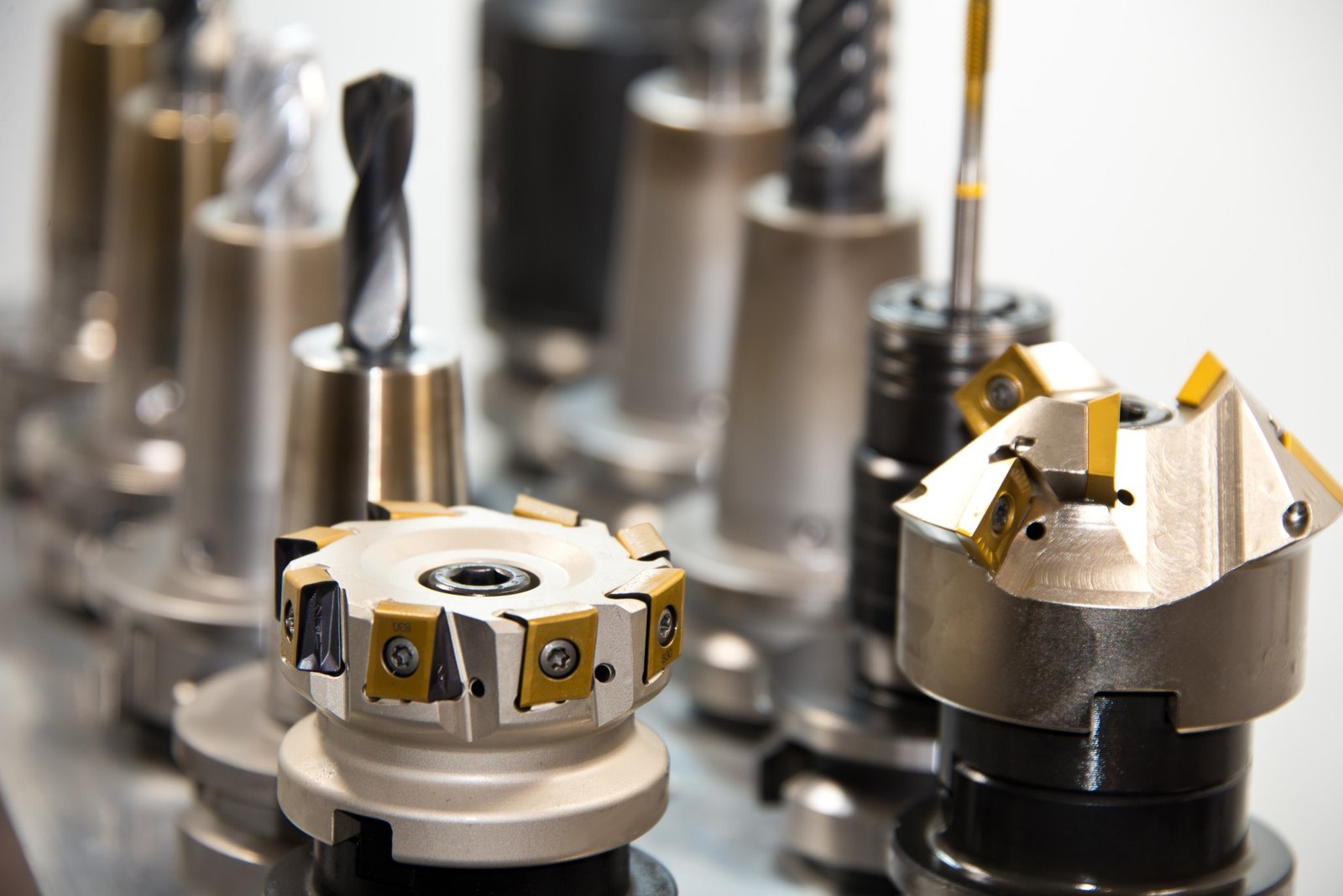

Cutter

Depending on the material and desired finish, the type of cutter used in CNC turning must be selected carefully. Harder materials require more powerful cutting tools and heat is also a factor in the selection process.

Tolerance

Tolerance is a crucial factor when it comes to CNC turning. This needs to be set up correctly so as not to affect the accuracy of the final product.

2. Different Types of CNC

CNC turning parts come in many different shapes, sizes, and materials, so it’s important to have a thorough understanding of what each of these entails. First, understand the types available, such as round bars, square bars, and stepped and profiled parts.

Second, understand the different materials that are suitable for turning. Steel, aluminum, brass, and plastic are the most common materials used, and each one requires a different cutting tool and approach.

Lastly, learn the cutting process which is used when producing these parts. Depending on the material and part geometry, a range of operations can be used, such as turning, facing, and drilling. Using the correct approach can reduce lead time and costs associated with production. Click this website for more information.

3. Advantages

CNC Turning Parts offer a range of advantages that make them a great choice for businesses. Firstly, there is the accuracy that they provide, since the machine eliminates human error. This means that parts can be fabricated exactly as specified, with minimal wastage.

Secondly, turning parts results in faster production speeds and improved quality control. Using a computer to operate the machine, they can arrive to the customer faster than ever.

Finally, many turning parts can produce complex parts with much less manual labor compared to traditional methods. This means that businesses can produce parts faster, at a lower cost, and with less waste.

Learning About CNC Turning Parts

CNC turning parts are complex components used for a variety of purposes. To understand their full potential, you need to know their functions, material, and accuracy. This article has provided insight into how to fully grasp the concept of CNC turning parts.

For more great advice and tips, check out our blog daily.